Fair Haven is a Diverse Community with a Rich History and a Beautiful Waterfront

-

Labeling Machine

- Vista, CA

- United States

- Blog Posts

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

Packaging Machine Factory Testing: What California Buyers Should Expect

For California manufacturers, packaging machine purchases carry added risk. Regulatory scrutiny, strict safety requirements, diverse product lines, and compressed production schedules leave little margin for equipment that is not fully production-ready at delivery.

Factory testing exists to reduce that risk—but many buyers misunderstand what factory testing should actually validate.

In packaging machinery, factory testing means verifying that a machine or complete packaging line performs correctly with real production variables before it ships to the customer’s facility. For California buyers, this step is critical to protecting startup timelines, regulatory compliance, and operational stability.

This article explains what effective factory testing includes, where expectations often break down, and how California manufacturers can use factory testing to avoid costly installation surprises.

Why Factory Testing Is Especially Critical for California Manufacturers

California production environments often combine:

- High SKU diversity

- Strict labeling and safety requirements

- Audits and inspections

- Tight customer delivery schedules

When packaging machines arrive untested under realistic conditions, problems are discovered during installation—when downtime is most expensive and regulatory pressure is highest.

For California buyers, weak factory testing increases the risk of:

- Missed production deadlines

- Compliance issues during inspections

- Extended commissioning and troubleshooting

- Unexpected engineering modifications on site

Factory testing is the last controlled opportunity to verify performance before equipment becomes part of a regulated production environment.

Where Buyer Expectations Commonly Break Down

Many buyers assume that factory testing simply means the machine runs before shipment. That assumption leads to serious gaps in validation.

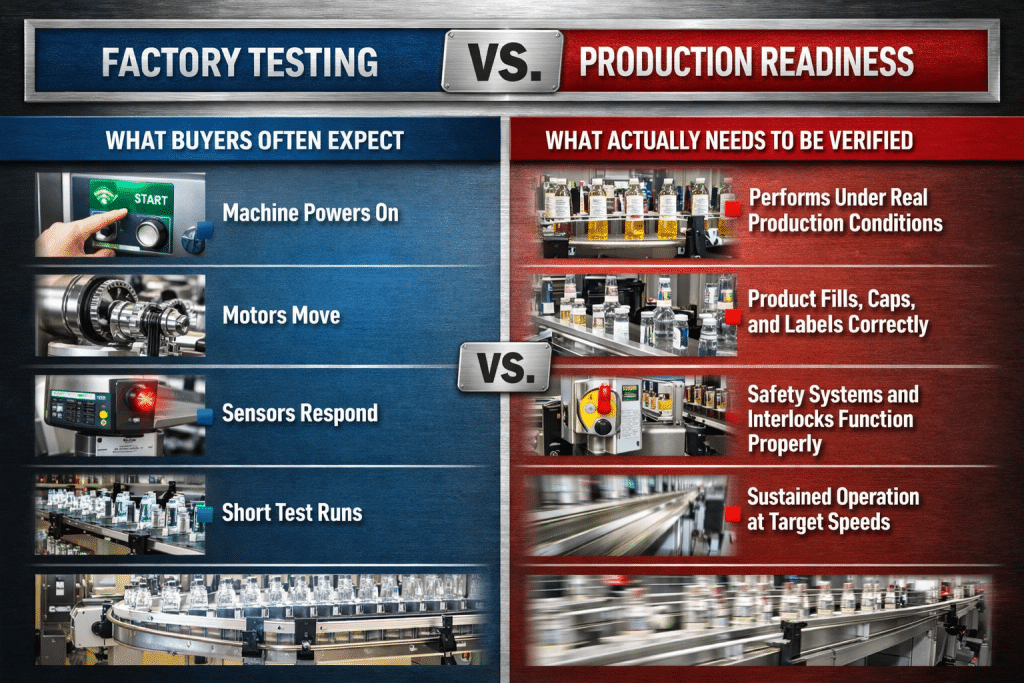

Factory Testing vs. Production Readiness

What Effective Factory Testing Should Include for California Buyers

Proper factory testing evaluates how the packaging machine behaves under the same constraints it will face in production.

1. Product, Container, and Closure Validation

Machines should be tested using:

- Actual or equivalent containers

- Real product or validated simulants

- Intended closures and label materials

This verifies:

- Fill accuracy and consistency

- Cap torque and seal integrity

- Label adhesion and placement under real conditions

These factors directly affect regulatory labeling accuracy and consumer safety.

What Effective Factory Testing Should Include for California Buyers

Proper factory testing evaluates how the packaging machine behaves under the same constraints it will face in production.

1. Product, Container, and Closure Validation

Machines should be tested using:

- Actual or equivalent containers

- Real product or validated simulants

- Intended closures and label materials

This verifies:

- Fill accuracy and consistency

- Cap torque and seal integrity

- Label adhesion and placement under real conditions

These …

The post appeared first on Accutek Packaging Machine Equipment.

Packaging Machine Scalability for Contract Manufacturers

For contract manufacturers, packaging equipment rarely fails because it breaks. It fails because it can’t adapt. New clients bring new containers, different fill volumes, tighter tolerances, and unpredictable production ramps. Packaging machines that cannot scale with these changes quickly become operational liabilities.

In packaging machinery, scalability means the ability to increase output, add new SKUs, or expand functionality without replacing the entire packaging line. For contract manufacturers, scalability is not a growth feature—it is a requirement for staying competitive.

Why Scalability Matters More for Contract Manufacturers Than Anyone Else

Unlike single-brand producers, contract manufacturers operate in constant transition. One month may require short runs of specialty products; the next may demand sustained higher throughput for a national brand.

Packaging machinery must support:

- Frequent SKU changeovers

- Multiple container shapes and sizes

- Variable production volumes

- Rapid onboarding of new client requirements

Machines designed for a single product or fixed output struggle in this environment. Scalable packaging machines are engineered to change with the business, not resist it.

What “Scalable Packaging Machinery” Actually Means in Practice

Scalability is often misunderstood as speed. In reality, it is about expandability without disruption.

Engineering Concepts Translated into Outcomes

| Engineering Design Element | What It Means Operationally |

|---|---|

| Modular machine frames | Additional stations can be added instead of replacing the machine |

| Servo-driven motion control | Accurate adjustment for different products and container formats |

| Open PLC architecture | New equipment can be integrated without rebuilding controls |

| Tool-less changeover components | Faster transitions between jobs with less downtime |

These design principles allow packaging machinery to grow incrementally—protecting both uptime and capital investment.

Scalable Filling Systems for Variable Products and Volumes

Filling is often the first operation affected by scalability limitations. Contract manufacturers may fill thin liquids, viscous products, foamy solutions, or volatile materials—sometimes on the same line.

Scalable filling machine design focuses on:

- Interchangeable filling heads and metering systems

- Adjustable fill profiles and stroke lengths

- Expandable configurations that allow additional heads to be added

- Compatibility with upstream and downstream equipment

Rather than replacing the filling machine as volume increases, scalable systems allow output to grow by adding capacity, not complexity.

Capping and Labeling Must Scale With Filling — Not After It

Packaging lines only scale as well as their weakest machine. A scalable filling machine loses its value if capping or labeling cannot keep pace.

Where Scalability Often Breaks Down

| Packaging Function | Common Scalability Issue | Engineering-Based Solution |

|---|---|---|

| Capping | Different closures require new machines |

…

The post appeared first on Accutek Packaging Machine Equipment.

Labeling Machine's Page

Profile Information

- Where do you live?

- Fair Haven Heights

- How long do you live in the area?

- 1-2 years

© 2026 Created by Adam Rendall.

Powered by

![]()

Comment Wall

You need to be a member of Chatham Square Association to add comments!

Join Chatham Square Association